|

Anders Eliasson -> RE: Building Guitar Number 100. (Sep. 24 2012 21:37:16)

|

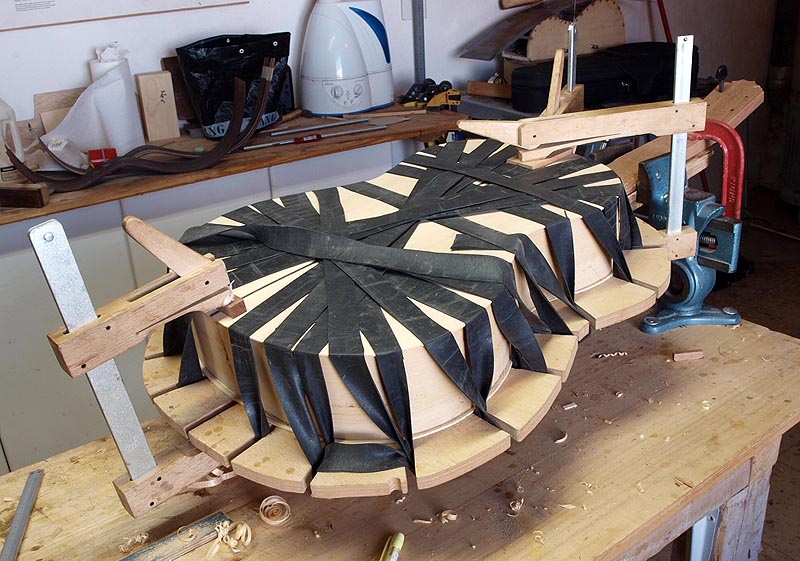

Its a difficult question to answer. But on a classical guitar you look for more tension on the top. That the top is more controlled. When you use a system where the central braces have more angle, you get more cross grain stiffness and more tension on the top. It gets less floppy so to say.

A thing that I forgot to write is that the braces going along the grain, the center braces, being 5, 6 or 7, more or less angle, more or less flamenco or classical are there first of all to avoid that the tension of the string will make the soundboard warp. This you can see very clearly on a guitar with to light a bracing or/and to thin a top. Then the soundboard starts dishing in front of the bridge and lift behind the bridge. So, a very important thing is to get the soundboard and the braces stiff enough, but not more than enough. To much stifness results in poor dynamics and an uncomfortable guitar to play

|

|

|

|