|

Ramón -> RE: Building a Flamenco Guitar - 4 (May 9 2006 3:25:56)

|

Hola all,

I have just returned from 6 days away on business (ugh - 12 hour days, 6 days), so I'm just reading all the responses and input! Thanks!

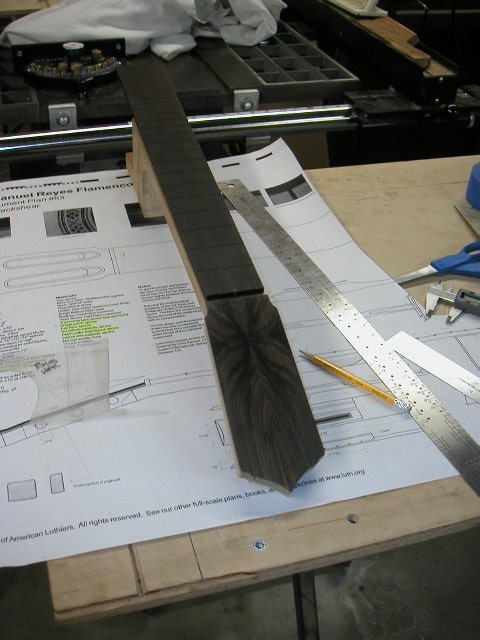

Bob Hein, the builder here, uses the Romanillos method at the neck, with the wedges. I was tempted to use it, but in talking to Tom Blackshear, he suggested I either build the plan - or just build whatever... I have decided to stick to the plan, as drawn. There is just a 'side-thickness' slot on either side of the neck for the sides, and I can use a very thin wedge to take up any gap I might have, although a 'dry run' shows it to be quite snug. The Romanillos method is quite nice - but why build a Reyes if I am not building a Reyes, tu sabes?

Also, I have left the appropriate thickness to the fretboard, etc., for final sanding and leveling BY HAND.

Today, I cut all my braces, leaving all slighty thick, so they will be 'tuned by hand' as I begin the back and top. Tom Blackshear says there is a "slight curve from bridge to back edge of the guitar"..."slight"....Is that a unit of measure??? So I am going to add a 1/8" thick piece of masonite to the back edge of the solera, up to the bridge, and feather the edges and back to '0'...There are many areas of this plan somewhat open to interpretation...Even with Bob's experience, he's curious as to the lack of many details and measurements...

Used some VERY straight-grained German Spruce for my braces, soundhole backing, etc., and all are laid onto a flat board for a bit more air/curing.

I have a tremendous new-found respect for builders and their prices...lol...Struggling with the decision to build a rosette, or use the one I have....

R

Images are resized automatically to a maximum width of 800px

|

|

|

|