|

constructordeguitarras -> Laugh about my saw blade (Dec. 3 2023 2:58:01)

|

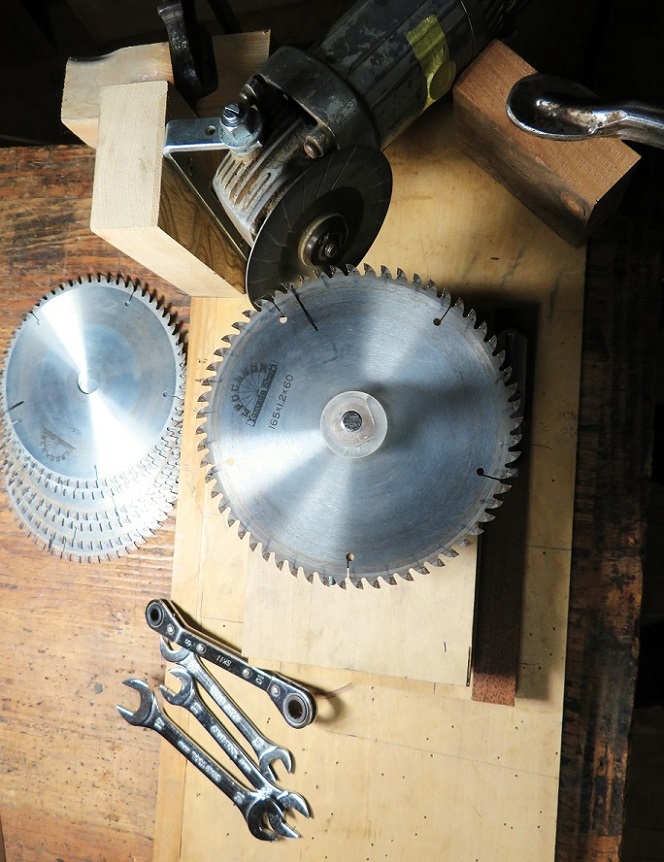

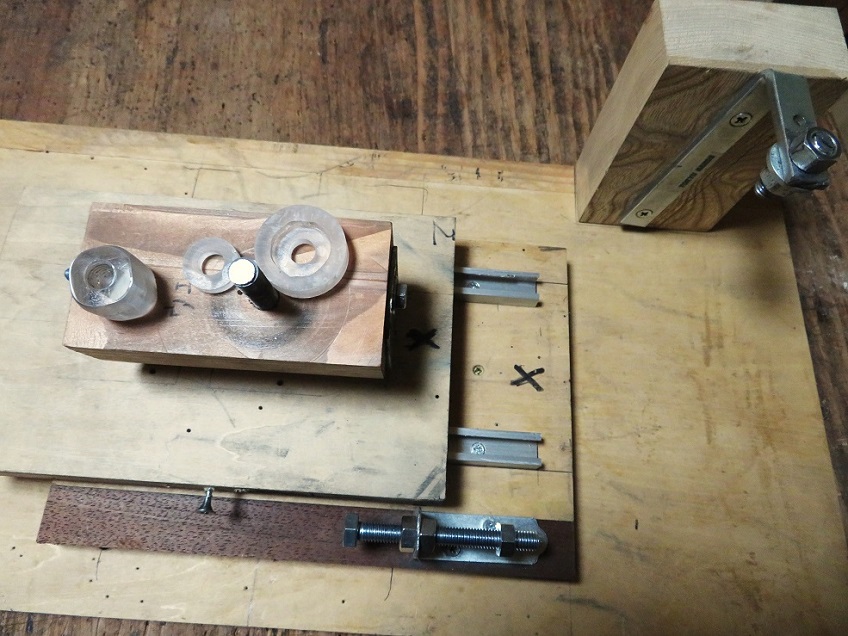

I like to make my guitar sides 1/16 inch thick and use a table saw to cut the slots in the neck to receive them. I find that the table saw blades that proclaim to leave a 1/16-inch kerf are actually around 0.07" instead of 0.0625" thick. I have a carbide-tipped one and several all steel ones that are like this. The steel ones were very cheap (around $10 each) and it occurred to me that I could adjust the thickness of one by running it through my Performax 16-32 drum sander. I was hesitant because I didn't really want metal filings in the sander and the idea of possible kickback with a sharp blade occurred to me. But I figured, what did I have to lose? It's a cheap blade and a used sanding belt that didn't cost much either. So, standing to the side of the machine and taking very light cuts, I did the job and it worked okay. Except the conveyor belt on the sander was a replacement one that I had installed ten years ago and is made of rubbery plastic. Which melted in spots due to the heat generated from sanding and conducted through the metal. As I was working I thought the melted areas, which were dark, were just metal dust that I would remove later. They weren't. And the conveyor belt which cost $100 ten years ago now costs $175 to replace. Some cheap blade I made. I just thought you would enjoy laughing at me.

|

|

|

|