|

kitarist -> RE: Solera Flamenca Strings (Dec. 13 2020 5:34:28)

|

quote:

ORIGINAL: JasonM

Wow, I didn’t know that. Interesting. So if there are only 3 nylon formulations, what does each string brand do differently to be unique besides change diameter? Are they specifying density or additives, maybe? I know the Aquila guy experiments with additives.

Aquila is its own universe; apart from extruding their own nylon strings, they also utilize new materials they discovered, for example their nylgut (synthetic gut string) which is a type of polyester; the sugar polymer; also blends of sugar and nylgut (as you can actually mix those); also other things specially for g-strings. So I'll put them aside for the moment, even for the nylon question you asked.

The string companies have very limited options to be different; apart from marketing and combining in sets and choosing different plastics producers.

They have to rely on the plastics producers to make the actual strings, and those are offered in standard diameters from a given plastics producer. Maybe across the few producers there is in total a larger variety offered if they sell slightly different diameters but it's not clear if that's the case (I've only seen the DuPont availability sheet for Tynex).

Also there is no ability to make different PA 612. Though due to working conditions at the plastics plant or some proprietary differences in the manufacturing process (which is not public info) there might be some slight property differences like stiffness. (but keep in mind nylon stiffness varies with temperature and relative humidity anyway).

So essentially if you know what the exact nylon is - say PA 612 - that pretty much locks in the physical and musical properties apart from the diameter.

The "real" reason the plastics producers offer PA 612 is for toothbrushes (and for some paintbrushes) bristles. They would only make transparent, black, or white; unless some custom order - but musical nylon strings are a tiny market compared to that for toothbrushes, paintbrushes, or even for fishing line (the latter PA 6 or PA 66 so no good for guitar strings; unless it is PVDF "carbon" but here we are just talking about the nylon options).

For example the 28,32,40 mils sizes (i.e. 0.028, 0.032, 0.040 in, or approx. 0.71, 0.81, 1.01mm for e, b, g trebles) happen to be on the DuPont Tynex availability list among others, and they are good for medium tension nylon trebles. But you can't order say 28.6 mils for e-treble from DuPont to be different from other string companies - it is simply not on the availability list, so you have to see what other diameters other plastics producers offer, if any different; or just stick with 28 mils.

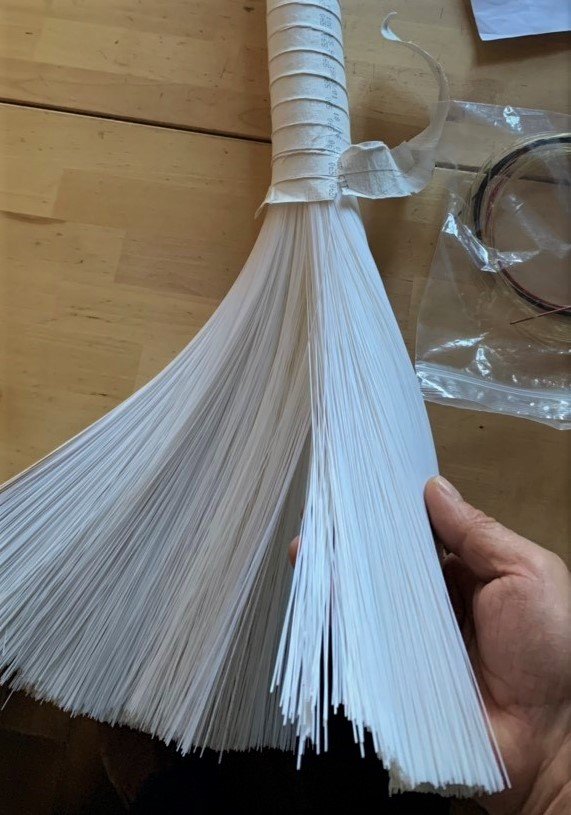

They sell them to string companies in 'hanks' of about 1.5-2 kg - a bundle some 4-5cm diameter with hundreds of straight nylon strings inside, at whatever standard length DuPont, say, chooses, like "117cm +- 3cm".

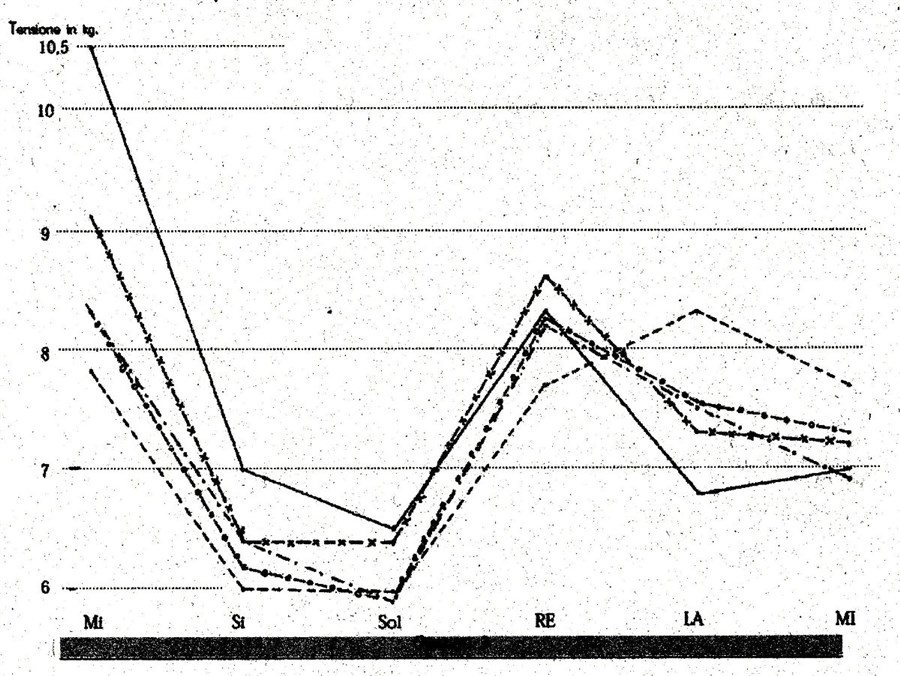

One interesting thing to keep in mind is that the 'identical' strings in that bundle are not identical in diameter between one another but vary in a Gaussian sense around the mean diameter. So for example a bundle with 0.71 mm strings would have a Gaussian distribution inside of diameters from about 0.70 to 0.72, or larger variation if quality control was not very tight. This is a consequence of having dies with up to 250 holes to make that many strings simultaneously in the extrusion process: there are (unavoidable) micro-differences in temperature across that die so even if the holes are identical, the strings come out with slight variation in diameter.

The string companies can add some colour dye but that's about it in terms of customizing after the manufacturing at the plastics plant. Apparently that addition would not change the density appreciably.

quote:

ORIGINAL: JasonM

You can see Luthier’s machines in this video. I guess these are the winders you are referring to.

https://youtu.be/iImliDEX8Ik

Thanks, that's great. Yes, these are just winders. Nylon monofilament extruders are complex big machines and difficult to calibrate and run. And that's just for nylon varieties (PA =Polyamide). The extruders for "carbon" strings, i.e. for PVDF = Polyvinylidene fluoride, are a nightmare to run as there's risk, unless monitored very tightly, while in process, of explosion, or decomposition of the melted polymer, and of release of hydrofluoric (HF) acid which is like the stuff of horror movies[:D] (Side note - it is what some of the "Breaking Bad"'s main characters used for dissolving... um... some "parts").

However, once the carbon string is produced, it is extremely stable chemically and non-absorbing, which is why PVDF is what pipes, bottles and filters in nanopure water or other ultra-clean systems are made out of.

|

|

|

|