|

RobF -> RE: Scarf joint (Feb. 28 2020 20:08:33)

|

Actually, Stephen Eden has already alluded to the solution, which is to start with the wood closer to the final dimensions. Everything kind of falls out of that. But I’ll throw in some thoughts, hopefully not too jumbled (the day has turned out to be more hectic than expected so I’m typing fast).

When the head is dimensioned by planing, the relationship between the break of the head at the nut and the location of the edge of the join at the back changes, with the nut break moving towards the heel. This can be countered by dimensioning the neck from the top to move the nut back to where it started. In other words, if 1mm is removed from the head, then planing 1mm off the neck (as a taper from the heel to nut) will move the break back to where it started. It’s good to get some practice with planing the neck from the top at any rate, it’s not that big a deal, the trick is to maintain square at the nut’s breakpoint at all times. So, when planing the head to final thickness keep the break square to the neck and then use callipers at the end of the head to ensure the head remains dimensionally consistent. Generally, I aim for about 17mm, which allows for a 2mm headplate and a 1mm veneer stack, but this is just a design decision, although a 20mm final dimension is pretty standard. Then when planing the neck portion, again keep everything square at the nut and all will be well. Just keep checking the dimensions at the opposite end of the neck and use a straightedge to make sure nothing untoward is happening.

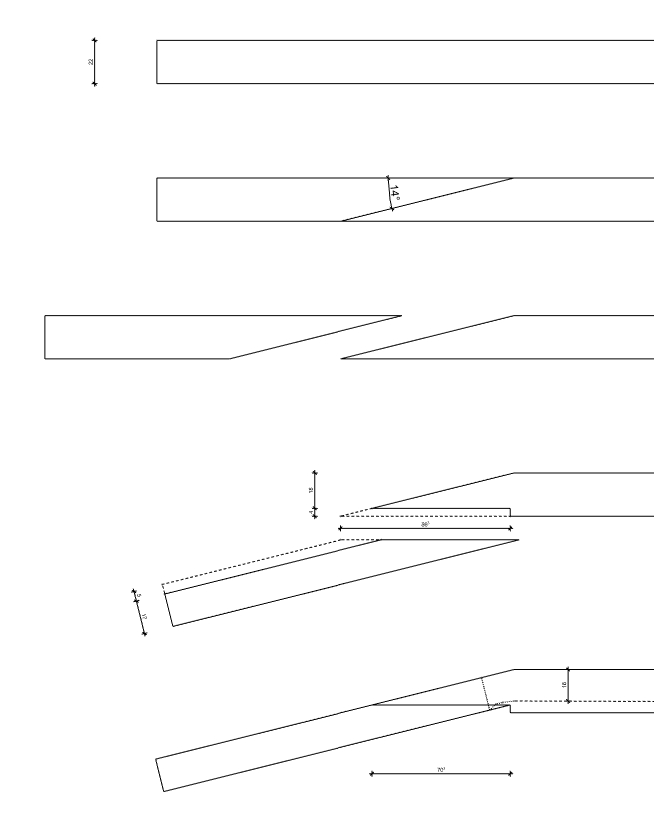

Now, if the neck is tapered to final dimensions (eg. 16mm at the nut, 18mm at the tenth) and the nut break and head scarf edge underneath all line up, and everything is square, then there is no need for a ridge to hide the scarf, as the cylindrical nature of the neck at that point will give the appearance of a nice gentle arc to the join, which can then be blended in with the arc towards the sides of the head.

But if a ridge is desired (as shown in the picture) or is required due to leaving the neck a consistent thickness during the build (in this case it was 18mm) then the taper is achieved while carving the neck, and the neck depth reduction at the nut will result in the formation of a ridge where the head drops into the neck’s taper. The trick is to match the cut of the ridge to the location of the join. Doing so makes it almost invisible.

Bottom line is SEden pretty well nailed it. Start with a neck dimension of 18-19mm and either reduce the head thickness by an additional millimetre before making the join (as Andy indicated), or reduce it after the join, but always pay attention to where the nut is going. Some planing of the head after joining is going to be necessary, regardless, so I tend to start with the same 18-19mm thickness for the head and neck and reduce the head’s dimension after the joining. Then I decide whether I want to achieve the taper from the front or if I will do the tapering during the carve. Sometimes the decision is just due to how well the neck’s going to plane, sometimes the nut break and join line up pretty nicely without attacking the front so planing doesn’t make sense, it depends. I generally try to have the direction of any runout oriented to facilitate planing, but that’s determined in part by the material at hand, and isn’t always practical. So I tend to decide on an ad hoc basis.

|

|

|

|