|

Ruphus -> RE: Building a Student Model (Jun. 19 2014 10:38:38)

|

I am surprised how appealing this inspiring thread is even to fellas like me who never built a guitar.

And it contains generally useful clues, like that clamping of a plane, using permanent wedges etc.

With its working routine and great explanation & pics supposedly worth a pin in the luthier section.

quote:

ORIGINAL: SEden

You just cant beat fine Japanese steal!

Seems the Chinese have not found out about such yet. Instead of buying from their neighbour, I read their tourist´s prime purchase in Germany during `Europe-in-3-days´ tours or so being German steal products like kitchen knives and scissors from Zwilling.

These Japanese hand saws appear to have conquered the worlds DIY and tool markets. Even yours truely got himself one, eventhough likely of no special steal, as it was a cheap specimen.

I suspect their design to be practically intriguing. It seems to intuitively tell one´s eye that this saw can be handled well. ( And its teeth promise a smooth bite.)

quote:

ORIGINAL: SEden

I have always found that I end up doing more work to it later in the build to theres no point going all out with the cleaning now.

I am of the impression as if this could be efficient in general / advanced artisans´and workers´ experience.

It seems typical that a beginner will try to final a section right away, which then for some reason might end up more time consuming way to proceed, and more risking to result in mismatch with the whole of the work piece.

Like say when a beginner in drawing while working on a portrait will finish the eyes while the rest being merely lightly sketched. Only to then discover that all the detailed work was a waste, because of disproportionate overal dimensions.

Whereas a skilled painter tends to commonly advance the work evenly across the motif.

-

Anyway, great thread!

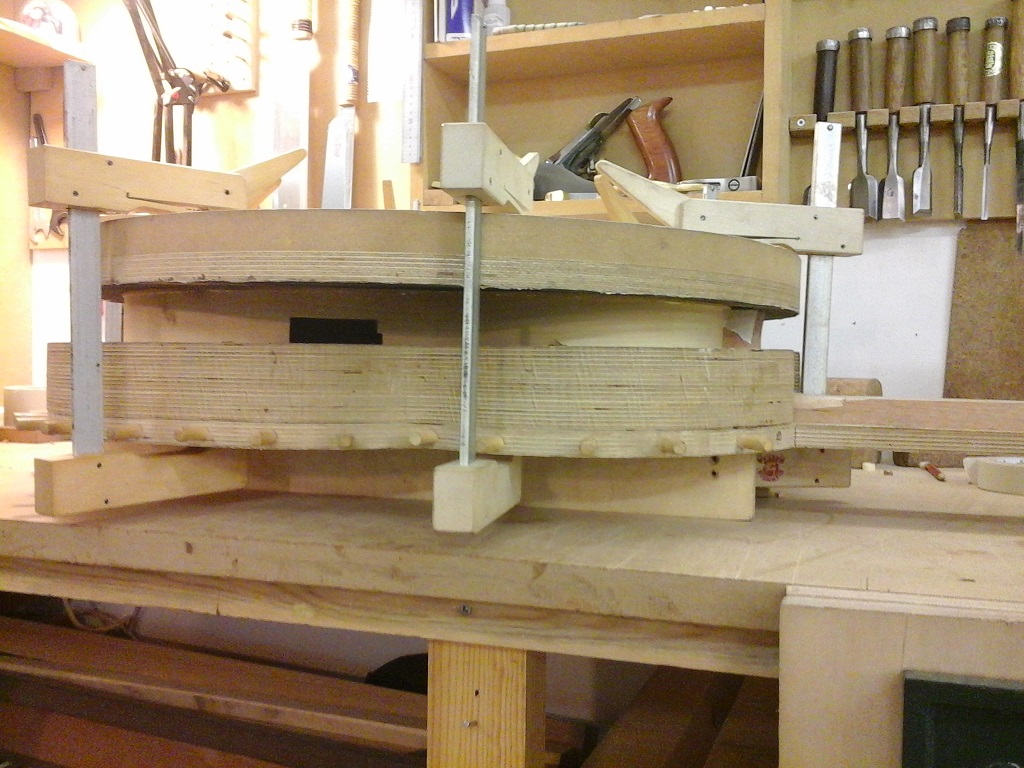

And thanks for showing the roller jig later!

Ruphus

|

|

|

|