Welcome to one of the most active flamenco sites on the Internet. Guests can read most posts but if you want to participate click here to register.

This site is dedicated to the memory of Paco de Lucía, Ron Mitchell, Guy Williams, Linda Elvira, Philip John Lee, Craig Eros, Ben Woods, David Serva and Tom Blackshear who went ahead of us.

We receive 12,200 visitors a month from 200 countries and 1.7 million page impressions a year. To advertise on this site please contact us.

|

|

|

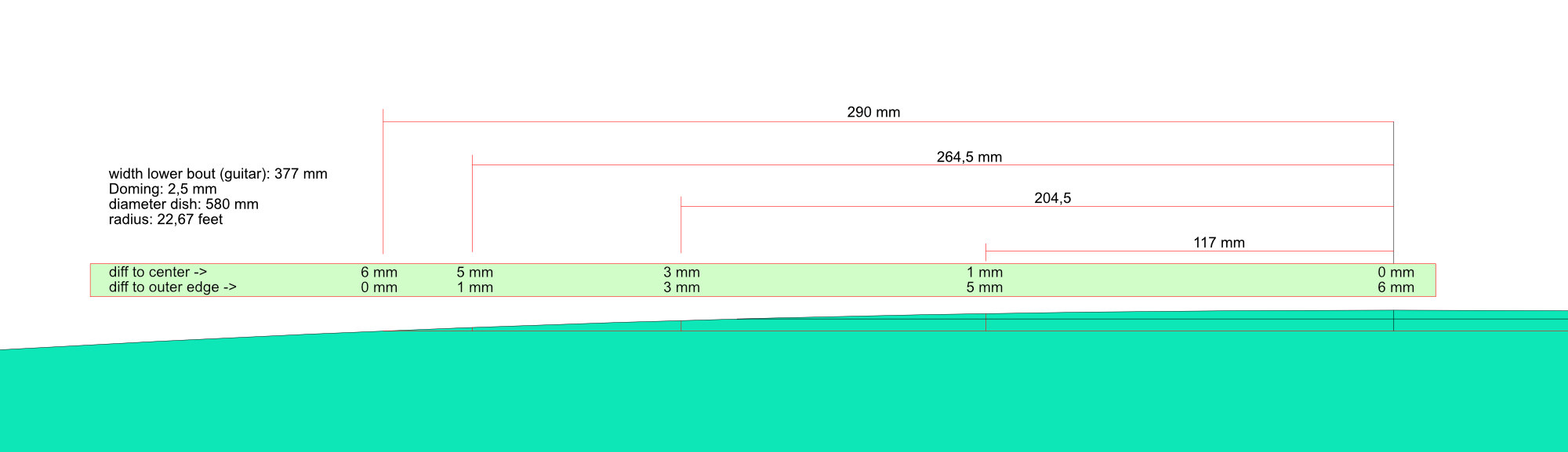

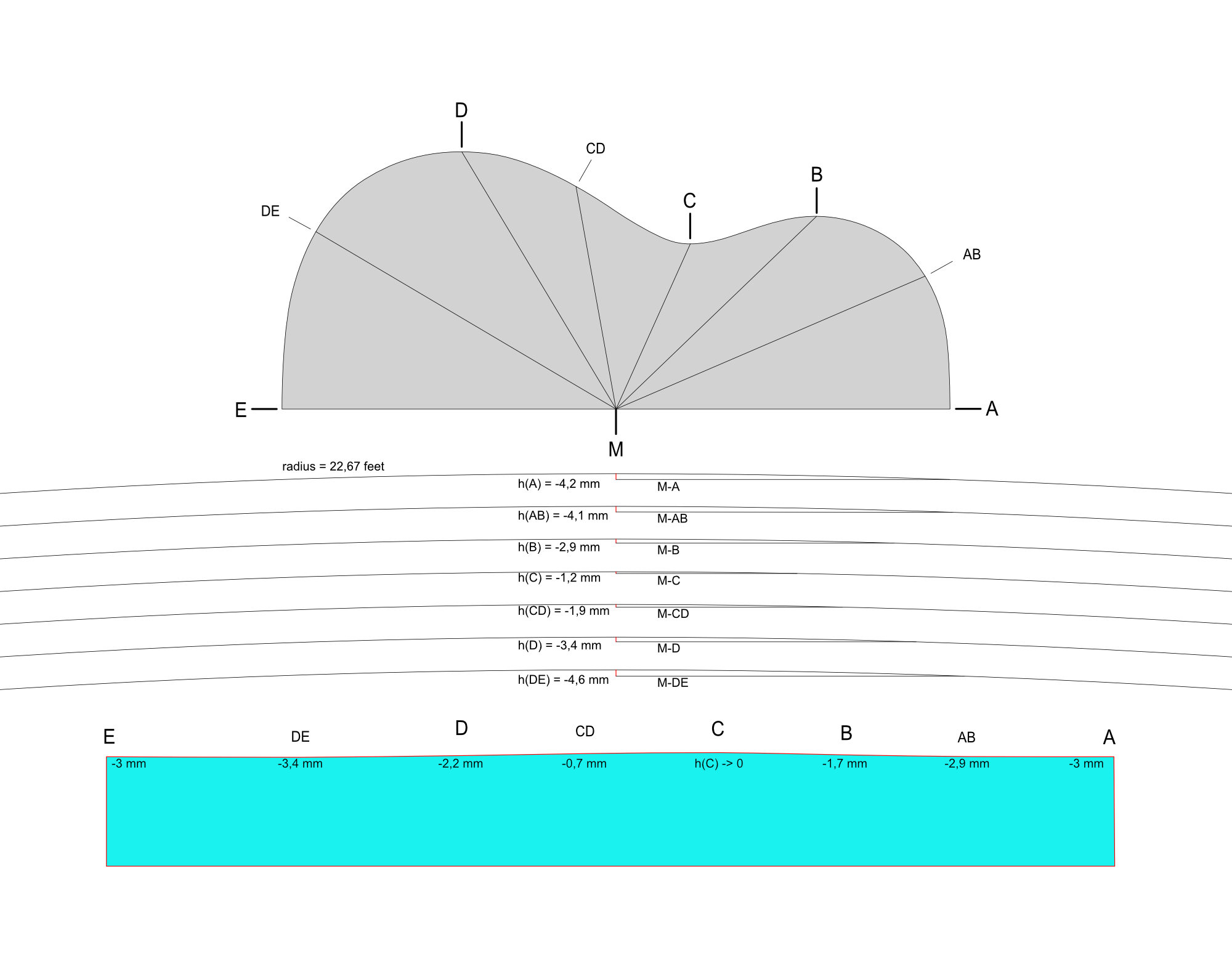

Shape the sides to fit a domed back in five minutes.

|

You are logged in as Guest

|

|

Users viewing this topic: none

|

|

Login  | |

|

RobF

Posts: 1611

Joined: Aug. 24 2017

|

RE: Shape the sides to fit a domed b... (in reply to Stefan Leon Kelly) RE: Shape the sides to fit a domed b... (in reply to Stefan Leon Kelly)

|

|

|

That huge tripod get-up is a pretty wild way to make a dish, doesn’t seem very practical.

So, before anyone goes and cuts a hole in their livingroom floor to accommodate the 15’ tripod in their basement - there’s an easier way. The explanation might look complicated but if a drawing is made while reading you’ll see that it’s actually quite simple. Just envision a router sled that would have two arcs as runners, but because arc templates may not be available, straight lines are used instead.

P.S. I’ve never actually made one of these, so the design might need some refining, lol. But the basic concept should work, I’m pretty confident about that part.

Here goes...

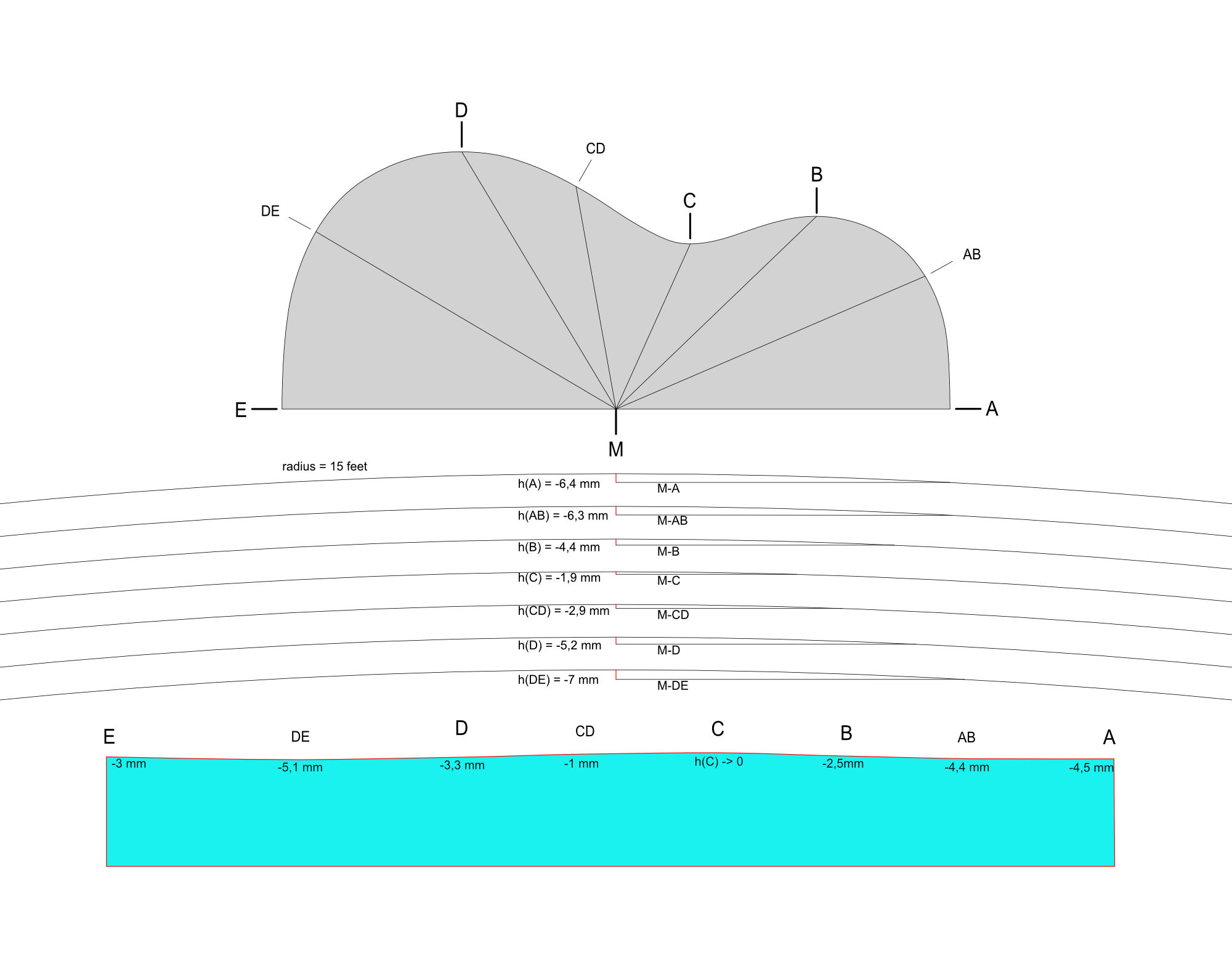

Take a piece of wood, say 3/4” X 4” X 60”, the dimensions are arbitrary but it has to be longer than twice the diameter of the dish being made. Mark one edge at the centre (30”, in this case). To make a 2’ diameter dish of 6mm depth, for example, make a mark one foot away from the centre and 6mm up from the edge of the board. Then plane a straight line that runs from the centre mark to the 6mm mark and then right to the end of the board. Repeat this on the other side of the centre mark. The board should now have a 15mm high triangular peak along the length of one edge.*

Make a duplicate piece and then make a platform for the router that can be fastened between the two pieces, with the router bit positioned to drop right at the peak in the centre. Make a couple more pieces the same width as the router platform and attach them at the ends to stabilize the structure. The result should be a sled with the router sitting at the centre between two runners.

To make the dish, take a piece of MDF or Plywood (the blank), and put it on a flat surface. The blank can be circular, but it doesn’t have to be. Take two supporting blocks, say 1/2” taller than the dish blank, and put them opposite each other close to, but not against (maybe 2 or 3 inches away), the side of the blank. Probably a good idea to screw them down. Also, probably good to make them the same width as the sled and put some side guides on them to stop the sled from moving about sideways. Sit the router sled on the supports, move the sled so the router bit is at the edge of the blank, and set the depth of router bit to touch the top of the edge of the dish.

Turn the router on and run it to the other side of the dish. If the dish is MDF there will be a large amount of fine dust created so it’s best to do this outside. The router bit will drop as the sled is moved towards the centre of the dish and rise as it moves away from the centre towards the supporting block on the other side. This will create a channel in the blank that defines an arc 2’ wide with a sagitta of 6mm. Rotate the blank between the supports and repeat the routs until the dish is formed. To aid in rotation and all round accuracy a dowel can be placed in the work surface dead centre between the guide platforms. Have it stick out about 1/2”. A corresponding 1/2” deep hole is drilled into the centre of the flat side of the dish and the dish can then pivot/spin on the dowel.

This can be used to dome the bridge area of the workboard/solera, too. Just drill the pivot hole in the desired location and rotate the workboard.

* For proof of concept, hold a pencil at the centre line peak of one of the boards. Drive two nails into a flat surface 2’ apart and rest the peaked side of the board against the nails. Run the jig along the nails so the pencil can make a line running from one nail over to the other. Have a look at the line and satisfy yourself that it describes an arc two feet wide with a sagitta of 6mm. You can also use this idea to make a router platform (with the router bit positioned perpendicular to the point of the peak) to make a radius stick to match the dish, which is a useful thing to have around the shop.

Highly detailed drawing done with my finger at 4AM:

Images are resized automatically to a maximum width of 800px

Attachment (1) Attachment (1)

|

|

|

|

REPORT THIS POST AS INAPPROPRIATE |

Date Oct. 18 2019 15:38:26

|

|

RobF

Posts: 1611

Joined: Aug. 24 2017

|

RE: Shape the sides to fit a domed b... (in reply to JasonM) RE: Shape the sides to fit a domed b... (in reply to JasonM)

|

|

|

I think there are no hard and fast rules when it comes to this, it’s really just up to the maker and what they are trying to achieve. I mentioned the 6mm difference because of how my eye perceives proportions. I generally go between 6 and 8mm.

I made a Reyes style about 5 or 6 years ago where I had a 4mm difference and felt it had a bit of a boxy look. It sounded great, however. Unfortunately, the owner of the shop that held it for consignment sold it, pocketed the money, put me down as an unsecured creditor (I wasn’t, it was never his property), declared bankruptcy and skipped town. So he basically stole it. I keep waiting for whoever has it now to show up with it for warranty work, lol, but I’ve never seen it since. I’ve never put one of my guitars up on consignment after that, not sure I ever will again.

Oh, and one of the reasons I posted about that dish making jig was to show how things can be made without resorting to a lot of calculations or complex machines. In that case, the whole jig can be set up using just a ruler to make a few basic straight line measurements. I have used side templates before, however, and probably will continue to, although I mainly just use a block plane for the basic shaping.

|

|

|

|

REPORT THIS POST AS INAPPROPRIATE |

Date Oct. 19 2019 21:17:02

|

|

New Messages New Messages |

No New Messages No New Messages |

Hot Topic w/ New Messages Hot Topic w/ New Messages |

Hot Topic w/o New Messages Hot Topic w/o New Messages |

Locked w/ New Messages Locked w/ New Messages |

Locked w/o New Messages Locked w/o New Messages |

|

Post New Thread

Post New Thread

Reply to Message

Reply to Message

Post New Poll

Post New Poll

Submit Vote

Submit Vote

Delete My Own Post

Delete My Own Post

Delete My Own Thread

Delete My Own Thread

Rate Posts

Rate Posts

|

|

|

Forum Software powered by ASP Playground Advanced Edition 2.0.5

Copyright © 2000 - 2003 ASPPlayground.NET |

0.078125 secs.

|

Printable Version

Printable Version

'))), I’d read the book but not examined the plans I cant spot the jig he used to help angle the sides, what page is it on?

'))), I’d read the book but not examined the plans I cant spot the jig he used to help angle the sides, what page is it on?

New Messages

New Messages No New Messages

No New Messages Hot Topic w/ New Messages

Hot Topic w/ New Messages Hot Topic w/o New Messages

Hot Topic w/o New Messages Locked w/ New Messages

Locked w/ New Messages Locked w/o New Messages

Locked w/o New Messages Post New Thread

Post New Thread